EFFECT OF FLY ASH AND GRANULATED BLAST FURNACE SLAG ON THE PHYSICAL PROPERTIES OF GEOPOLYMER CONCRETE USE CORAL SAND AND SEAWATER

Coastal Branch of the Joint Vietnam - Russia Tropical Science and Technology Research Center

30 Nguyen Thien Thuat, Nha Trang, Khanh Hoa

Số điện thoại: 0984400436; Email: quanttndvn@gmail.com

Nội dung chính của bài viết

Tóm tắt (Abstract)

Geopolymer concrete is an eco-friendly material that possesses properties comparable to those of traditional Portland cement concrete. This study aimed to explore how the ratio of fly ash to blast furnace slag impacts the mechanical properties of geopolymer concrete using coral sand and seawater. Fly ash and blast furnace slag were used as binders alongside alkaline activators such as liquid glass and sodium hydroxide solution. The characteristics were assessed based on measurements of bulk density, water absorption, workability, compressive strength, and flexural strength. The compressive and flexural strengths of the samples increased gradually with the rising ratio of fly ash to blast furnace slag. Moreover, no significant differences were observed when comparing geopolymer concrete's flexural and compressive strengths using coral sand and seawater with those using river sand and freshwater. On the other hand, the FTIR analysis results indicate that the characteristic Si-O-Si(Al) bond of the geopolymerization reaction in the wavenumber range 950 to 1005 cm-1 is present in both types of concrete, with no significant difference observed. These findings suggest that river sand and freshwater in geopolymer concrete production can replace coral sand and seawater for geopolymer concrete.

Từ khóa (Keywords)

blast furnace slag, fly ash, coral sand, seawater, geopolymer concrete

Chi tiết bài viết

- Highlights:

Geopolymer concrete was successfully prepared using coral sand and seawater, achieving a compressive strength of up to 74.9 MPa.

Increasing slag content (FA/BFS from 70/30 to 30/70) enhanced compressive strength from 47.7 to 74.9 MPa.

Coral sand and seawater are viable, sustainable alternatives for geopolymer concrete.

1. INTRODUCTION

Can sea sand and seawater be used to make concrete in special cases, such as offshore islands, where transporting materials is difficult? This has been a topic of recent research and has shown promising results. Various methodologies for incorporating sea sand and seawater into concrete production have been extensively researched, specifically applying geopolymer concrete [1-4]. Many studies utilize coastal sand, which contains silica as the main component, as a substitute for river sand. However, in areas outside of islands, coral sand is primarily used, which consists mainly of CaCO3 along with a small portion of halite crystal phase (rock salt). Hence, studying coral sand as a fine aggregate in geopolymer concrete is crucial. Moreover, utilizing geopolymer concrete also aids in decreasing CO2 emissions in comparison to traditional cement concrete [5]. Given the current focus on sustainable development research and the objective of reducing CO2 emissions, it is imperative the transition to geopolymer concrete.

Unlike traditional cement concrete, in geopolymers produced through alkali activation, the C-S-H gel observed in traditional Portland cement is replaced by N-A-S-H or C-A-S-H gel [6,7]. As a result, the SO42- and Mg2+ ions in marine materials do not have the conditions necessary to form gypsum (CaSO4.2H2O), ettringite (3CaO.Al2O3.3CaSO4.32H2O), or brucite (Mg(OH)₂) in geopolymer concrete [8-10]. This is why harmful ions (Cl-, SO42-, Mg2+) in marine materials have little impact on geopolymer concrete's mechanical properties.

Geopolymers, derived from aluminosilicate materials such as fly ash, kaolin, silica fume, and blast furnace slag, are commonly employed as binding agents in highly alkaline environments, typically in conjunction with liquid glass or sodium hydroxide. When aluminosilicate hydrates are heated, the OH ions break apart to form water, and this starts the process of creating Si-O-Al bonds [11]. This reaction occurs when solid aluminosilicate oxides are exposed to alkali metal silicate solutions in highly alkaline conditions and moderate temperatures. The result is the formation of amorphous, semi-crystalline polymeric structures that contain Si-O-Al and Si-O-Si bonds. This reaction occurs when solid aluminosilicate oxides are exposed to alkali metal silicate solutions in highly alkaline conditions and moderate temperatures. The result is the formation of amorphous, semi-crystalline polymeric structures that contain Si-O-Al and Si-O-Si bonds. Additionally, the Si/Al ratios in the structure of binders used in the mixture also impact the bonding structure. [12,13]. Appropriately combined, these materials yield concrete products characterized by high compressive strength [14-17].

In this study, investigated the impact of fly ash and blast furnace slag on the physical and mechanical properties of geopolymer concrete using coral sand and seawater.

2. EXPERIMENT

2.1. Materials

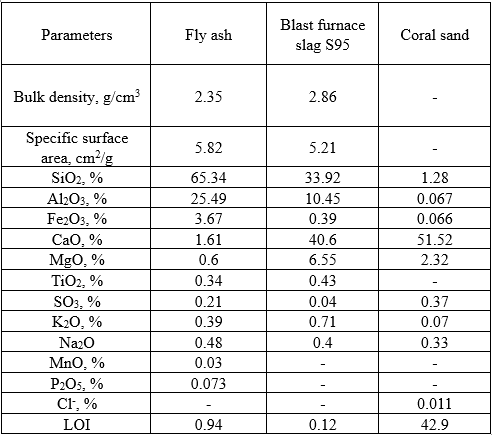

- Fly ash was obtained from a Van Phong 1 BOT Thermal Power Plant in the Van Phong Industrial Park in Khanh Hoa. Table 1 presents some of the parameters of the fly ash.

- Blast furnace slag S95 was obtained from Hoa Phat Group. Some parameters of fly ash are provided in Table 1.

- A 12M sodium hydroxide (NaOH) solution was prepared by dissolving 99% solid NaOH from Vietnam in water.

- The liquid glass solution was manufactured in Vietnam with a silicon modulus of about 2.5.

- Coral sand was sourced from offshore Truong Sa islands in Vietnam. The chemical composition of coral sand is detailed in Table 1.

Table 1. Parameters of fly ash,blast furnace slag S95 and coral sand

- Superplasticizer SR 5000F by SilkRoad.

- Seawater with parameters as indicated in Table 2

Table 2. Parameters of seawater.

2.2. Research Methods

2.2.1 Mix design

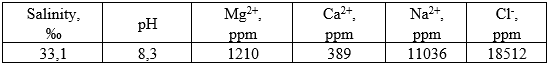

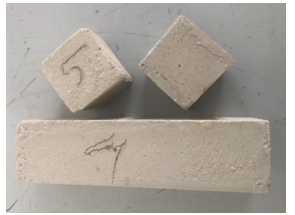

The material proportions in this study were determined based on previous research on geopolymer concrete that used river sand and freshwater [14-17]. Table 3 shows the mix proportions for various mass ratios of fly ash to blast furnace slag in one batch. This study's components, such as coral sand, seawater, and alkaline activation solution, remained constant.

The activated alkaline solution was created by combining a liquid glass solution with a 12 M NaOH solution in a 2.5:1 mass ratio.

In addition, sample GR-01 uses river sand and freshwater at the same ratio as sample GS-01 to evaluate the use of coral sand and seawater in geopolymer concrete.

After being shaped, the concrete samples were kept in the mould for 48 hours. Store samples at a temperature of approximately 27°C ± 2°C and a humidity of around 95% ± 5% throughout the process.

Table 3. Mixing ratio of concrete samples

2.2.2 Testing and Analytical Methods

- The particle size distribution was determined according to the TCVN 7572-2:2006 standard. A standard set of sieves with sizes of 0.14 mm, 0.315 mm, 0.63 mm, 1.25 mm, 2.5 mm, and 5 mm was used.

- The workability of the geopolymer concrete mixture was evaluated according to the TCVN 3106:2022 standard using a truncated cone measuring (100 x 200 x 300) mm.

- The density of the geopolymer concrete mixture was measured using a 1-litre standard container by TCVN 3108:2022. The density of the hardened sample was determined in line with TCVN 3115:2022.

- The concrete sample was inspected for water absorption according to TCVN 3113:2022, using samples of (100 x 100 x 100) mm in the dry state.

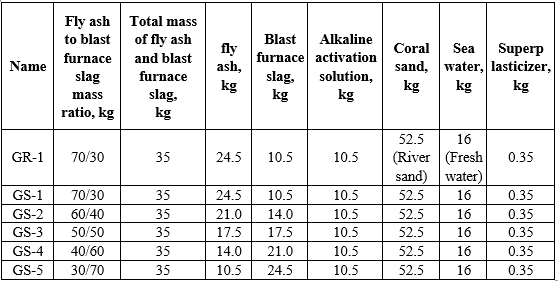

- The flexural strength was evaluated using TCVN 3121-11:2003 with a sample size of (40 x 40 x 160) mm. The compressive strength using a sample size of (40 x 40 x 40) mm. The test was conducted using an automated hydraulic compression system, TYA-2000. Figure 1 shows the experimental samples.

- Determine the chemical structure by FTIR from 600 to 4000 cm-1 at a resolution of 16 cm-1 for 32 scans (Cary 630 FTIR Spectrometer)

Figure 1. Samples of compressive and flexural strength tests

3. RESULTS AND DISCUSSION

3.1. Specifications of coral sand

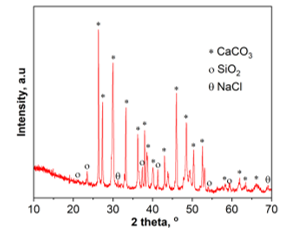

Figure 2 shows the X-ray diffraction (XRD) spectrum of coral sand, which indicates that it mainly consists of CaCO3, with a small amount of halite crystals present. This aligns with the details given in Table 1.

Figure 2. XRD spectrum of coral sand

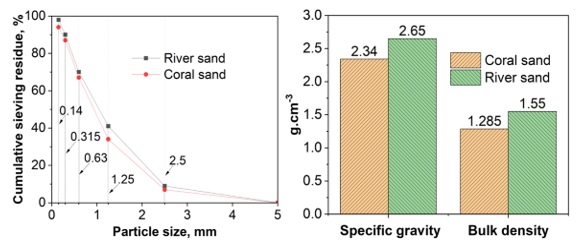

The size distribution of coral sand compared to river sand used for concrete is shown in Figure 3. The results show that the particle size distribution of coral sand is similar to that of river sand. Additionally, the specific gravity and bulk density of coral sand are approximately 11% and 17% lighter than river sand, respectively.

a) b)

Figure 3. (a) Particle size distribution, (b) specific gravity and bulk density

3.2. Physical properties of geopolymer concrete using coral sand and seawater

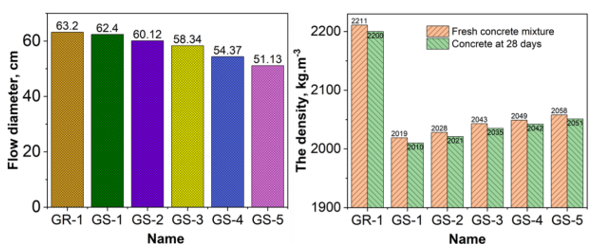

The workability of the fresh concrete mixture was evaluated using the flow parameter. Figure 4a shows how the flow of fresh concrete mixture was impacted by the mass ratio of fly ash to blast furnace slag. The flow decreased as the fly ash to blast furnace slag ratio decreased from 70/30 to 30/70. Specifically, The flow of the fresh concrete mixture decreased from 62.4 cm to 51.1 cm. This decrease occurred because the CaO content increased as the blast furnace slag content increased from 30% to 70%. As a result, there was a decrease in the amount of residual water after dissolving Ca2+ in the blast furnace slag, leading to a gradual decrease in the flow of the fresh concrete mixture after mixing. In addition, because this is a concrete mixture without coarse aggregate, the addition of a superplasticizer results in a concrete mixture with good workability, high plasticity, great uniformity, and no separation between components.

Coral sand has rougher surfaces and higher porosity, resulting in greater water absorption than river sand. As a result, the flow of the GS-1 sample is lower than that of the GR-1 sample (Figure 4a).

The density of the geopolymer concrete mixture from coral sand and seawater increased as the mass ratio of fly ash to blast furnace slag decreased, as shown in Figure 4b. The absence of coarse aggregate in GS concrete, coupled with the lower specific gravity of fly ash compared to blast furnace slag in the concrete mixture, accounts for this phenomenon. The density of the GS fresh concrete mixture ranges from 2019 kg/m3 to 2058 kg/m3, and for GS concrete at 28 days, it ranges from 2010 kg/m3 to 2051 kg/m3. The density of the GS sample is lower than that of the GR concrete sample that uses river sand due to the lower specific gravity of coral sand compared to river sand.

a) b)

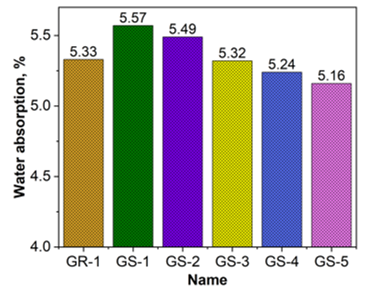

Figure 4. (a) Flow of fresh concrete mixture, (b) The density of concrete

Figure 5 illustrates the water absorption of the samples. The results indicate that using coral sand and seawater leads to increased water absorption. Cl- ions from coral sand and seawater do not react and remain inside the samples, causing local internal damage, increasing porosity and leading to increased water absorption. Elevating the blast furnace slag content in GS samples results in the formation of a greater quantity of calcium-rich gels, such as C-A-S-H, during the solidification process. This facilitates the filling of pores and leads to a denser structure. Consequently, the water absorption of GS samples diminishes with an escalation in blast furnace slag content.

Figure 5. Water absorption of concrete samples

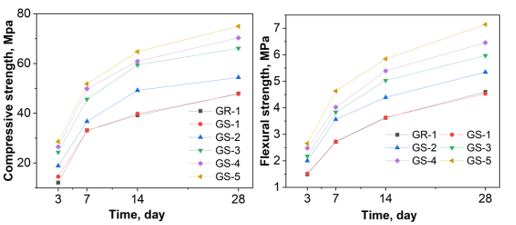

In Figure 6, it is evident that modifying the mass ratio of fly ash and blast furnace slag significantly influences the compressive and flexural strengths of GS concrete.

a) b)

Figure 6. (a) Compressive strength, (b) Flexural strength

It was observed that, following 28 days, the compressive and flexural strengths of the concrete improved with an increased mass of blast furnace slag. Specifically, the compressive strength of samples GS-1, GS-2, GS-3, GS-4, and GS-5 at 28 days was as follows: 47.7 MPa, 54.4 MPa, 66.1 MPa, 70.3 MPa, and 74.9 MPa, respectively. The flexural strength of samples GS-1, GS-2, GS-3, GS-4, and GS-5 at 28 days was as follows: 4.53 MPa, 5.34 MPa, 5.97 MPa, 6.45 MPa, and 7.14 MPa, respectively. The presence of CaO.xSiO2 in blast furnace slag causes a reaction with water, leading to the creation of a hydraulic effect that forms calcium-silicate (xCaO.ySiO2.zH2O). This process enhances the strength of geopolymer concrete. As the content of blast furnace slag increases, the amount of CaO dissolved in the activated alkaline solution also increases, resulting in the formation of C-A-S-H gels. These products aid in binding the separate aggregate components together, creating a solid structure and enhancing the strength of the concrete.

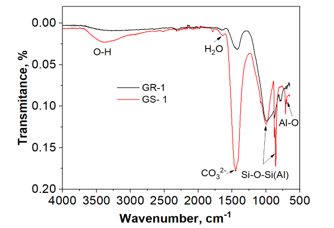

The comparison of the strength of GS-1 and GR-1 samples indicates that using coral sand and seawater instead of river sand and freshwater accelerates the achievement of compressive strength in concrete at 3 days old. This is due to the higher porosity of coral sand than river sand, which results in better water retention during casting and improved water release during hardening. Additionally, this process contributes to internal vulcanization, ultimately benefiting the increase in the compressive strength of the concrete. Moreover, the presence of Cl- ion in seawater also helps to speed up the hydration process of concrete, leading to early solidification. The compressive and flexural strengths of the GR-1 specimen were approximately 2% higher at 28 days. This increase may be attributed to the higher porosity of coral sand, resulting in lower stiffness than river sand, as well as the presence of unreacted Cl- from sea sand and seawater. However, the strength difference between the GS-1 and GR-1 specimens was insignificant. This was further confirmed by FTIR spectrum analysis (Figure 7). The results showed that the characteristic Si-O-Si(Al) bonds of the gel polymerization reaction wavenumber range of 950 cm-1 to 1005 cm-1 appeared in both GS-1 and GR-1 samples. The Si-O-Si(Al) bonds slightly shifted to higher wave numbers in geopolymer concrete using coral sand and seawater, indicating a slight decrease in cross-linked aluminosilicate gel [18]. Therefore, the compressive strength of geopolymer concrete using coral sand and seawater is slightly reduced compared to river sand and freshwater. In addition, the FTIR spectrum also confirmed that the CO32- functional group has superior strength in the concrete sample using coral sand because the main component of coral sand is CaCO3. Based on the results above, using coral sand and seawater instead of river sand and freshwater in geopolymer concrete appears to be a viable alternative.

Figure 7. FTIR spectra of GS-1 and GR-1 samples

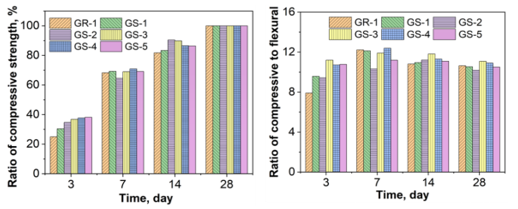

Figure 8a shows the ratio of the compressive strength of the sample over time compared to that at 28 days. The results show that the compressive strength at 3, 7 and 14 days respectively reached about (30 ÷ 38)%; (64 ÷ 71)%; (81 ÷ 91)% for GS samples; for GR-1 samples it reached about 25%; 68%; 82%. Furthermore, the ratio of compressive strength to flexural strength of GS samples fluctuated around 9 ÷ 12, which was similar to that of GR-1 sample (Figure 8b).

a) b)

Figure 8. (a) The ratio of compressive strength at different times to that at 28 days, (b) The ratio of compressive strength to flexural strength over time.

4. CONCLUSIONS

This study demonstrated the possibility of using coral sand as a fine aggregate and seawater to produce geopolymer concrete. Geopolymer concrete utilizing coral sand and seawater exhibits lower flow and water absorption than concrete with river sand and freshwater. In comparing the two types of concrete, there appears to be no significant difference in compressive and flexural strength. Initial evaluation using FTIR spectra indicated similar bonding properties in the gel polymerization reaction for geopolymer concrete using coral sand, seawater, and geopolymer concrete using river sand and freshwater. However, regarding geopolymer concrete using coral sand and seawater, a decrease in the fly ash/blast furnace slag ratio from 70/30 to 30/70 results in reduced flow and water absorption. This decrease is due to more calcium-rich gels, such as C-A-S-H, forming during curing. Notably, the compressive strength increases by approximately 57%, the flexural strength increases by around 42%, and the compressive strength to flexural strength ratio falls within the range of 9 to 12. As well as, the compressive strength of geopolymer concrete using coral sand and seawater at the ages of 3, 7, and 14 days was approximately 30÷38%, 64÷71%, and 81÷91%, respectively, compared to the compressive strength at 28 days.

Acknowledgments: This research is funded by the Joint Vietnam - Russia Tropical Science and Technology Research Center under grant number VB.Đ1.03/23

Author contributions: Le Hong Quan: contributed investigation, methodology, data curation, writing, original draft, review, and editing. Tran Van Tuan, Dong Van Kien, Nguyen Van Chi: performed investigation, review, and editing.

Conflict of interest statement: The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Tài liệu tham khảo

2. A. Fathima, K. K. Smitha, A review on feasibility of geopolymer sea sand concrete in interlocking concrete pavement blocks, Int. Res. J. Eng. Technol., Vol. 7 No. 2, pp. 2022-2026, 2020.

3. N. T. N. Vân, N. Q. Phú, Nghiên cứu sử dụng cát biển và tro bay chế tạo bê tông, Khoa học kỹ thuật Thủy lợi và Môi trường, Vol. 74, No. 6, pp. 62-66, 2021.

4. N. Q. Phú, N. T. Lệ, Nghiên cứu sử dụng cát biển, kết hợp tro bay và xỉ lò cao chế tạo bê tông geopolymer ứng dụng cho các công trình thủy lợi, Khoa học Công nghệ Xây dựng, Vol. 3, pp. 35-41, 2021.

5. J. Davidovits, Environmentally driven geopolymer cement applications in Geopolymer 2002 Conference, 2002, pp. 1-9.

6. J. Davidovits, High-Alkali cements for 21st century concretes, Spec. Publ., Vol. 144, pp. 383–398, 1994.

7. S. Luhar, D. Nicolaides and I. Luhar, Fire resistance behaviour of geopolymer concrete: An overview, Buildings, Vol. 11, pp. 82, 2021. DOI:10.3390/buildings11030082

8. A. L. Almutairi, B. A. Tayeh, A. Adesina, H. F. Isleem and A. M. Zeyad, Potential applications of geopolymer concrete in construction: A review, Case Stud. Constr. Mater., Vol. 15, pp. 00733, 2021. DOI:10.1016/j.cscm.2021.e00733

9. T. V. Lâm, V. K. Diến và B. B. Igorevich, Nghiên cứu sử dụng kết hợp tro bay nhiệt điện với xỉ lò cao để chế tạo bê tông chất lượng cao hạt mịn không xi măng, Tạp chí Xây dựng, Vol. 10, pp. 183-190, 2021.

10. S. Luhar, I. Luhar, Application of seawater and sea sand to develop geopolymer composites, Int. J. Recent Technol. Eng., Vol. 8, No. 5, pp. 5625-5633, 2020. DOI:10.35940/ijrte.E5681.018520

11. Boyaci, The geopolymer behavior of metakaolin and spinel structures of different kaolins., Master’s Thesis, Kütahya Dumlupınar University/Institute of Science, Kütahya, Turkey, 2018

12. M. Komljenovic, Z. Bascarivic and V. Bradic, Mechanical and microstructural properties of alkaliactivated fly ash geopolymers, J. Hazard. Mater., Vol. 181, pp. 35–42, 2010. DOI:10.1016/j.jhazmat.2010.04.064

13. S. Greiser, G. Gluth, P. Sturm and C. Jäger, 29Si{27Al}, 27Al{29Si} and 27Al{1H} double-resonance NMR spectroscopy study of cementitious sodium aluminosilicate gels (geopolymers) and gel-zeolite composites, RSC Adv., Vol. 70, pp. 40164–40171, 2018. DOI:10.1039/C8RA09246J

14. M. G. Norton, J. L. Provis, 1000 at 1000: Geopolymer technology—the current state of the art, J. Mater. Sci., Vol. 55, No. 28, pp. 13487-13489, 2020. DOI:10.1007/s10853-020-04990-z

15. S. Parathi, P. Nagarajan and S. A. Pallikkara, Ecofriendly geopolymer concrete: a comprehensive review, Clean Technol. Environ. Policy, Vol. 23, No. 6, pp. 1701-1713, 2021. DOI:10.1007/s10098-021-02085-0

16. S. Yang, J. Xu, C. Zang, L. Rui, Q. Yang and S. Sun, Mechanical properties of alkali-activated slag concrete mixed by seawater and sea sand, Constr. Build. Mater., Vol. 169, pp. 395-410, 2019. DOI:10.1016/j.conbuildmat.2018.11.113

17. A. Kamel, N. Marija, Z. Yibing and Ye Guang, A review on the durability of alkaliactivated fly ash/slag systems: advances, issues, and perspectives, Indus. Eng. Chem. Res., Vol. 55, No. 19, pp. 5439-5453, 2016. DOI:10.1021/acs.iecr.6b00559

18. A. Rafeet, R. Vinai, M. Soutsos and W. Sha, Effects of slag substitution on physical and mechanical properties of fly ash-based alkali activated binders (AABs), Cem. Concr. Res., Vol. 122, pp. 118–135, 2019. DOI:10.1016/j.cemconres.2019.05.003